Pre-Engineered Steel Building industry is rapidly gaining ground around the world and it has its imprints in construction projects across various fields in the manufacturing sector, including textile, pharmaceutical, and automotive sectors in India. At present Pre Engineered Steel, the building industry is experiencing a rapid growth rate due to macro-level projects as well as the growth of the market pie itself with more sectors looking at PEB as a viable construction solution.

The most distinctive advantages of utilizing a Pre —Engineered Steel Building are the cost-effectiveness in material, time-efficiency in fabrication, erection, and aesthetically pleasing in finishing. Thus, having the intention to invest in a Pre-Engineered building for your business requirements is definitely one of the smartest choices that a company can make. It is important to understand and identify a truly trusted and reliable Pre Engineered Building Supplier distinguished itself from the others. Pre Engineered Buildings can be adapted to suit a wide variety Of structural applications. This guide intends to give you the information necessary to make a smart and informed purchase of a new Pre -Engineered Steel Building.

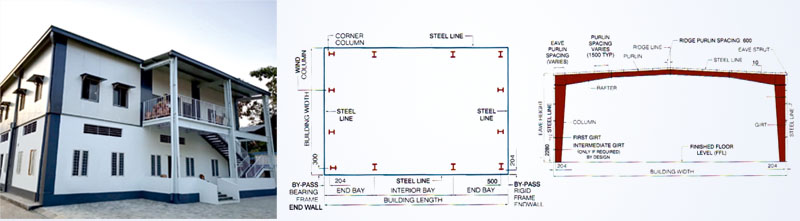

Basic Building Parameters: The PEB Steel structure of a building comprises of interior rigid frames, endwall bearing or rigid frames, endwall wind columns, secondary structural members (roof purlins & wall girts), wind bracing components and the structural framing of optional subsystems such as roof monitors, mezzanines (inclusive of mezzanine deck and deck fasteners), roof extensions, canopies, fascias, parapets, interior partitions, roof & wall framed openings, anchor bolts, connection bolts and sag rods.

Building width. No matter what primary framing system is used, the building width is defined as the distance from outside of eave struct/purlin of one sidewall to outside of eave struct of the opposite sidewall.

Building length. For flush endwalls, the distance between the outside flanges of endwall columns in opposite endwalls is considered the building length. For by-pass endwalls the distance between the outside of wall girts in opposite endwall is considered the building length. Building lengths is the sum of all bay lengths. For maximum ceconomy maintain equal interior bay length and make the end bays shorter than the interior bays. An example would be a 100 m long building that has 11 interior bay lengths 8 m and 2 end bay length of 6 m.

Roof Slope (x/10). This is the angle of the roof with respect to the horizontal. The ideal roof slopes is 1/10. Any practical roof slop is possible

Interior Bay Length. Interior bay length is the distance between the center lines of columns of two adjacent interior rigid frames. The most common interior bay lengths in the PEB industry are 6, 7.5.8, 9 and 10m. The most economical range of interior bay length is 7.5 - 8.5m.

End Bay Length. For flush endwalls girts the end bay length is the distance from the outside of the outer flange of endwall columns to center line of the columns of the first interior rigid frames. For by-pass endwall girts the end bay length is the distance from the outside of endwall grits to the center line of the columns of the first interior rigid frame. For maximum economy limit the end bay length to 6m or less and use by pass endwall grits.

Building Height. Building height is defined by the eave height which is the distance from bot tom of base plate to the top outer point of the eave strut/purlin. Eave heights upto 30m are possible.

Steel Line is the plane of the out of secondary "Z" & "C" members (or the inside of panels)

Typical Purlin Spacing is 1500 mm but may be higher or lower as required by design. Ridge purlin spacing is 600 mm to accommodate optional 600 mm ridge gravity ventilators. It is higher when a roof monitor is specified.

Eave Purlin Spacing is generally the balance distance of all purlins spacing unless it exceeds 1500mm, in which case it is divided into two spaces.